3D Printing: indivudual

We have added a high-performance Keyence Agilista 3D printer to our technical portfolio for testing fixed mechanical and high-precision designs.

The printer can print transparent, movable and temperature-resistant prototypes with fatigue strength at 80°C.

Furthermore, it can print flexible silicone materials with different Shore hardnesses.

Machine parameters:

| Type: | Keyence Agilista-3200W |

| Building space: | 297 mm / 210 mm / 200 mm (W/D/H) |

| Material: | UV-curing model material & water-soluble support material |

| Layer resolution: | min. 15 µm (0.015mm) |

| Application areas: | Manufacturing of high-precision, media-resistant and semi-transparent components |

Increased flexibility and speed

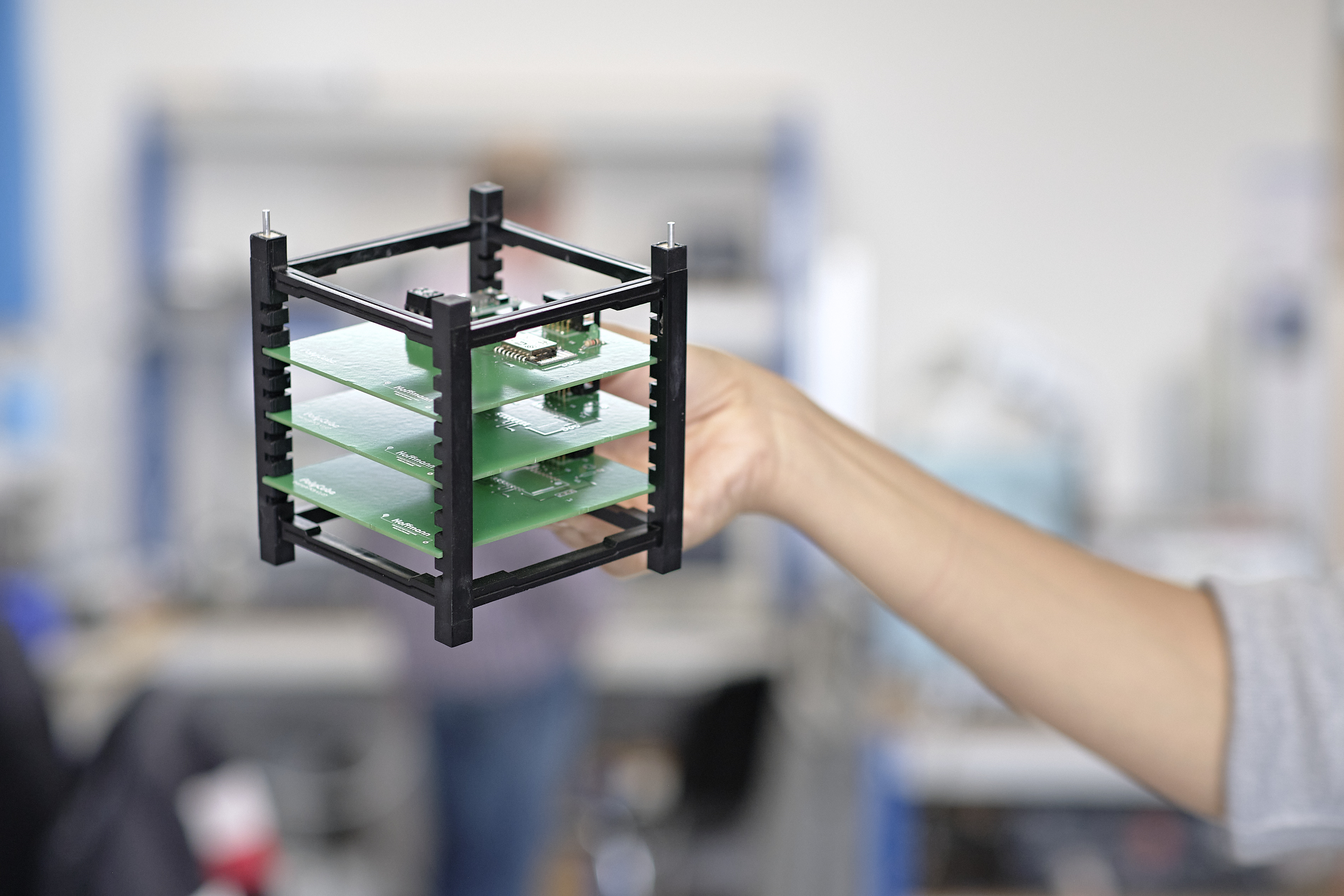

Direct prototype printing for our development, e.g. for Intelligent Haptics, is just one of the possible applications.

With this, we can finally get our hands on your ideas even faster and work with you to make optimizations or adjustments and see if the component really fits your application.

Printed injection mold

Printing the individual parts for a high-strength plastic injection mold. Another advantage of the printed mold is that it is partially transparent, making it easy to see and find any problems.

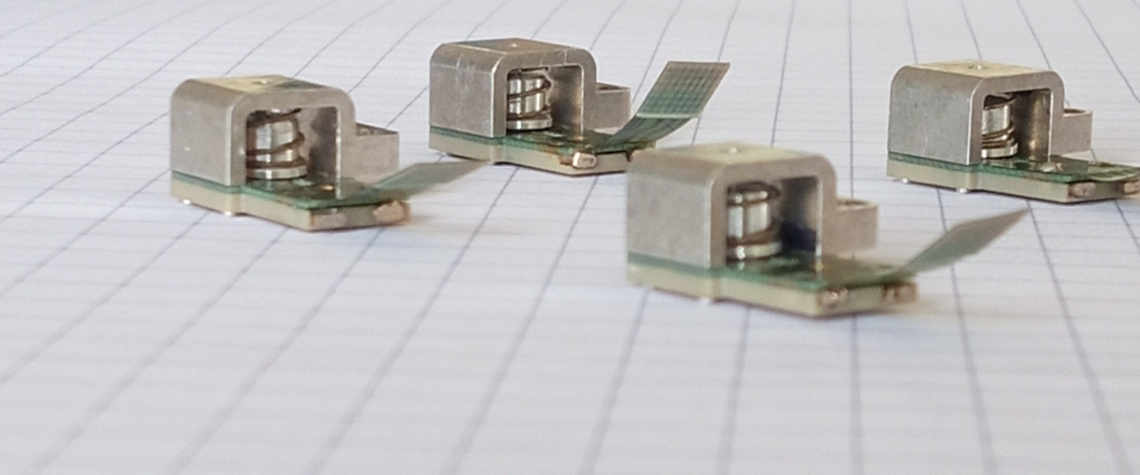

Printing of silicone components

As we are one of the specialists for two-component injection molding (2K), our 3D printer can also print two components. For example, the co-printing of silicone seals of different Shore hardnesses is possible.

Printing of Moving Parts

Another speciality is that moving parts can also be printed, as the support material (used to support them during printing) is water soluble.